Home Product OVEN > LJ-933 Single Modular Cement Dryer

LJ-933 Single Modular Cement Dryer

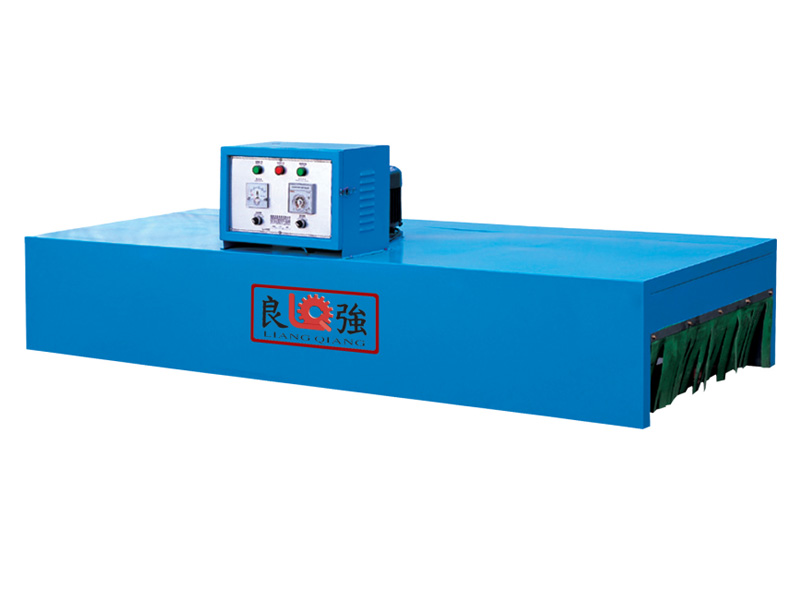

Stand-alone-units setup

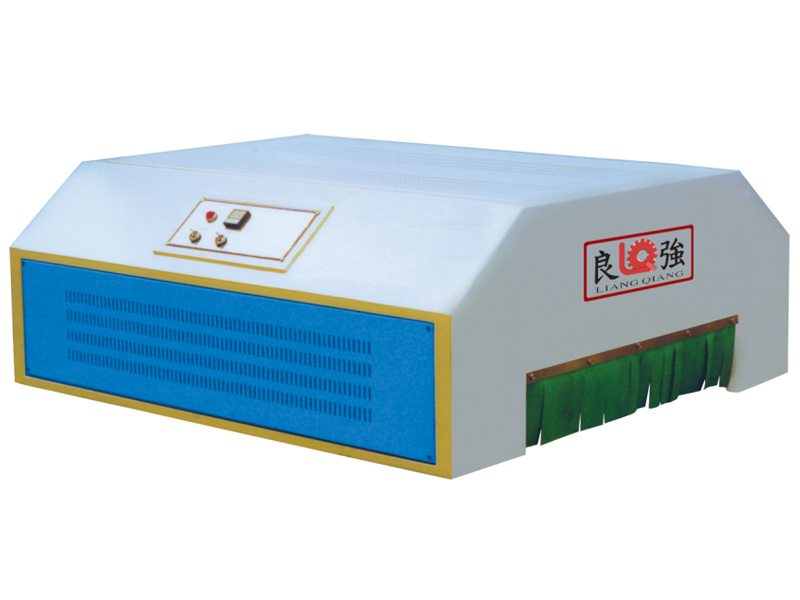

Serial modular setup

Single-side access

U-shaped design

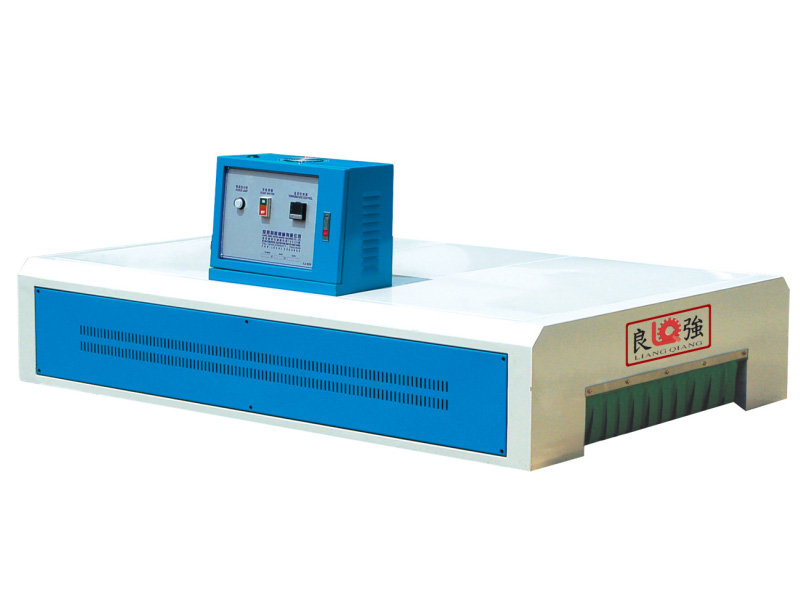

Air purification system

Ultimate energy saving

Serial modular setup

Single-side access

U-shaped design

Air purification system

Ultimate energy saving